- Home

- Equipment

- Aro

- Air Operated Double Diaphragm Pumps in UAE

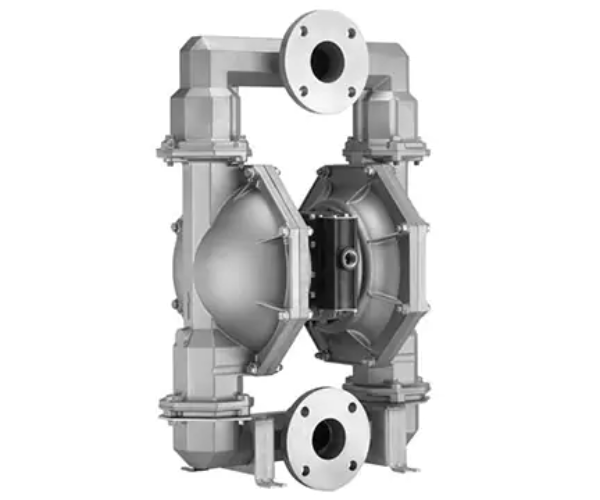

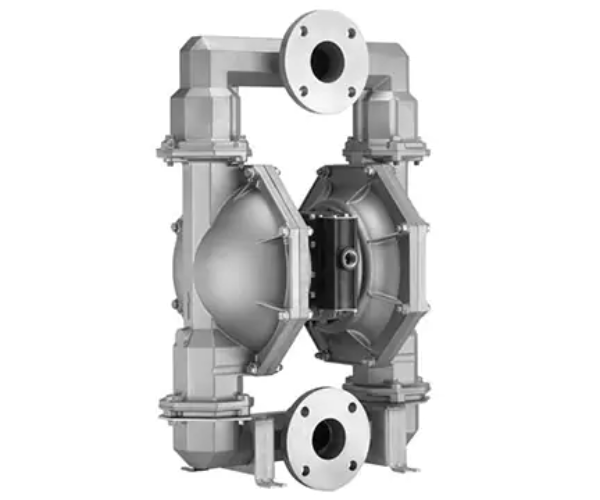

- ARO 3'' EXP Metallic Air Operated Diaphragm Pump

ARO 3'' EXP Metallic Air Operated Diaphragm Pump

The ARO 3" EXP Metallic Air Operated Diaphragm Pump is an advanced industrial pump designed to meet the high-demand requirements of various industries, including ceramics, paint, oil & gas, chemical, and petrochemical sectors.

Returns & Refunds Policy

Warranty Against Defects

Original Products

Ships Worldwide

Dedicate Support

- Description

- Brand

- Features

- Specifications

- Performance

- Dimension

- Performance Curve

- Accessories

- Materials

The ARO 3" EXP Metallic Air Operated Diaphragm Pump is an advanced industrial pump designed to meet the high-demand requirements of various industries, including ceramics, paint, oil & gas, chemical, and petrochemical sectors. Its standout features make it a leading choice for applications such as transfer, filling, recirculation, and batching.

-

High Performance:

- Capable of flow rates up to 275 GPM (1040.9 LPM).

- Operates with exceptional efficiency and durability.

-

Unique Convoluted Diaphragm Design:

- Extends diaphragm life by up to 4 times longer than conventional designs.

-

Enhanced Efficiency:

- Equipped with the Simul-Shift™ valve for a reliable, positive shift signal.

-

Exceptional Reliability:

- ARO's proprietary 'Unbalanced' air valve ensures no-stall operation, even under demanding conditions.

-

Broad Compatibility:

- Offers multiple construction materials to ensure compatibility with a wide range of fluids.

-

Environmentally Conscious:

- Bolted construction design prevents fluid leakage, supporting environmental safety.

-

Ease of Maintenance:

- Modular architecture simplifies servicing, minimizing downtime.

Model Series: PX30A-XXX-XXX-CXXX, PX30S-XXX-XXX-CXXX

Pump Type. . . . . . Metallic, Air Operated,

Double Diaphragm

Ratio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1:1

Material Inlet / Outlet (female)

PX30X-AXX-XXX-CXXX. . . . . . . . . . . . 3 - 8 NPTF - 1

PX30X-BXX-XXX-CXXX. . . . . . . . . . . . Rp 3 (3 - 11 BSP parallel)

PX30X-DXX-XXX-CXXX. . . . . . . . . . . . 3” ANSI Flange (4 Holes)

PX30X-FXX-XXX-CXXX. . . . . . . . . . . . 3” DIN Flange (8 Holes)

Air Inlet (female). . . . . . . . . . . . . . . . . . . . 3/4 - 14 NPTF - 1

Air Exhaust (female). . . . . . . . . . . . . . . . . 1-1/2 - 11-1/2 NPT

Weight . PX30A-XAX-XXX-CXXX. . . . . . 129.5 lbs (58.8 kgs)

PX30A-XCX-XXX-CXXX. . . . . . . 221.1 lbs (100.3 kgs)

PX30A-AHX-XXX-CXXX, BHX. 249.8 lbs (113.3 kgs)

PX30A-ASX-XXX-CXXX, BSX. . 228.8 lbs (103.8 kgs)

PX30A-FHX-XXX-CXXX, DHX. . 269.6 lbs (122.3 kgs)

PX30A-FSX-XXX-CXXX, DSX. . 245.6 lbs (111.4 kgs)

[add 40.0 lbs (18.2 kgs) for Stainless steel air motor section]

Air Section Service Kit. . . . . . . . . . . . . . 637421

Fluid Section Service Kit (without Seats)....... 637303-XX

Fluid Section Service Kit (with Seats).............. 637303-XXX

Air Inlet Pressure Range. . . . . . . . . . . . 20 - 120 psig (1.4 - 8.3 bar)

Maximum Material Inlet Pressure. . . 10 psig (0.69 bar)

Fluid Outlet Pressure Range. . . . . . . . 20 - 120 psig (1.4 - 8.3 bar)

Maximum Flow Rate . . . . . . . . . . . . . . . . 237 gpm (897 lpm)

flooded inlet. . . . . . . . . . . . . . . . . . . . . . . 275 gpm (1,041 lpm)

Maximum Particle Size. . . . . . . . . . . . . 3/8” dia. (9.5 mm)

Maximum Temperature Limits (diaphragm / ball / seat material)

E.P.R./EPDM. . . . . . . . . . . . . . . . . -60° to 280° F (-51° to 138° C)

Hytrel®. . . . . . . . . . . . . . . . . . . . . . -20° to 180° F (-29° to 82° C)

Nitrile. . . . . . . . . . . . . . . . . . . . . . . 10° to 180° F (-12 to 82° C)

PVDF (Kynar®).. . . . . . . . . . . . . . . 10° to 200° F (-12° to 93° C)

Santoprene®. . . . . . . . . . . . . . . . -40° to 225° F (-40° to 107° C)

PTFE. . . . . . . . . . . . . . . . . . . . . . . . 40° to 225° F (4° to 107° C)

Viton®. . . . . . . . . . . . . . . . . . . . . . . -40° to 350° F (-40° to 177° C)

Displacement / Cycle @ 100 psig . . . 2.8 gal. (10.6 lit.)

Noise Level @ 70 psig - 50 cpm . . . 83.0 dB(A)

| A | D | J | L | N | G | |

| PX30X-XAX-XXX-CXXX | 23-5/8” (600.1 mm) | 2-3/8” (60.3 mm) | 11” (279.4 mm) | 15-1/2” (393.7 mm) | 2-3/4” (69.9 mm) | 32” (812.8 mm) |

| PX30X-XCX-XXX-CXXX | 23-5/8” (600.1 mm) | 2-7/16” (61.9 mm) | 11-11/16” (296.9 mm) | 15-1/2” (393.7 mm) | 2-3/4” (69.9 mm) | 32” (812.8 mm) |

| PX30X-XHX-XXX-CXXX | 23-1/8” (587.4 mm) | 2-3/4” (69.9 mm) | 11-11/16” (296.9 mm) | 16” (406.4 mm) | 2-3/4” (69.9 mm) | 32” (812.8 mm) |

| PX30X-XSX-XXX-CXXX | 23-1/8” (587.4 mm) | 2-3/4” (69.9 mm) | 11-11/16” (296.9 mm) | 16” (406.4 mm) | 2-3/4” (69.9 mm) | 32” (812.8 mm) |

| PX30X-DXX-XXX-CXXX | 23-1/8” (587.4 mm) | 2-3/4” (69.9 mm) | 11-11/16” (296.9 mm) | 16” (406.4 mm) | 3-3/4” (95.25 mm) | 33-15/16”(862.0mm) |

| PX30X-FXX-XXX-CXXX | 23-1/8” (587.4 mm) | 2-3/4” (69.9 mm) | 11-11/16” (296.9 mm) | 16” (406.4 mm) | 3-3/4” (95.25 mm) | 33-15/16”(862.0mm) |

- 66109 Air Line Connection Kit: contains Piggyback Filter / Regulator, pipe nipple & 5’ section of hose

- 67237 Diaphragm Failure Detection Kit

- 67350-1 Cycle Counter Kit

- 67263 Continuous-Duty Muffler

- 67174-30 Screen Inlet Adapter Kit

- 637369 Air Section Service Kit for PX30R

- 637421 Air Section Service Kit for PX30A and PX30S

- 637303-XX Fluid Section Service Kit

Pump Casing Materials:

- Aluminum: Lightweight and cost-effective.

- Cast Iron: Durable and suitable for abrasive applications.

- Stainless Steel: Corrosion-resistant for chemical applications.

- Hastelloy-C: Excellent for highly aggressive or acidic fluids.

Diaphragm Materials:

- Long Life PTFE: Superior chemical resistance and longevity.

- Santoprene: General-purpose elastomer with good chemical compatibility.

- Hytrel: Flexible with excellent durability for dynamic applications.

- Nitrile: Resistant to oils and petroleum-based fluids.

- PTFE with Santoprene backer: Combines the benefits of PTFE with added support for longevity.

- Viton: Excellent resistance to aggressive chemicals and high temperatures.