- Home

- Equipment

- Aro

- Air Operated Double Diaphragm Pumps in UAE

- Liquid Control Accessories

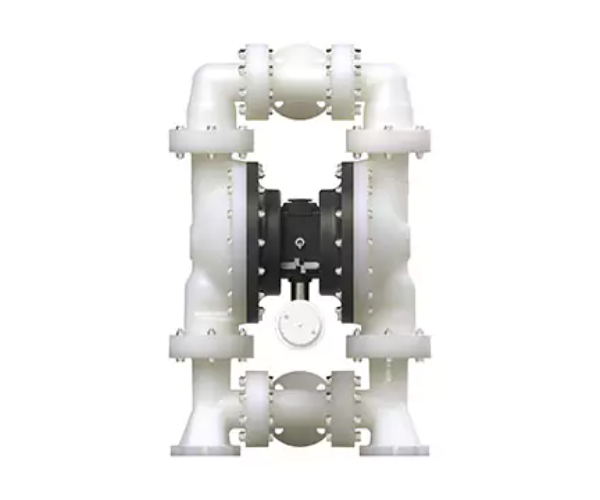

- ARO 3'' EXP Non-Metallic Air Operated Diaphragm Pump

ARO 3'' EXP Non-Metallic Air Operated Diaphragm Pump

The ARO 3'' EXP Non-Metallic Air Operated Diaphragm Pump stands out for its efficiency, reliability, and innovative features.

Returns & Refunds Policy

Warranty Against Defects

Original Products

Ships Worldwide

Dedicate Support

The ARO 3'' EXP Non-Metallic Air Operated Diaphragm Pump stands out for its efficiency, reliability, and innovative features. Designed for high-demand applications, this pump offers significant performance improvements and is built to minimize total cost of ownership.

Performance Highlights

- Flow Rates: Capable of handling up to 285 gpm (1,079 lpm), providing a 55% increase in flow compared to the ARO EXP 2” pump.

- EXP Air Motor Design: Ensures efficient and faster transfer of materials.

Material Options for Durability

- Pump Casing Materials:

- Polypropylene: Known for chemical resistance and durability.

- PVDF: Offers high resistance to aggressive chemicals.

- Diaphragm Options:

- Long-Life PTFE: Ideal for extended use in challenging conditions.

- Santoprene®, Hytrel®, Buna-N, and PTFE with Santoprene® backer: Suitable for various application needs.

Advanced EXP Features

- Cost Efficiency: Tested to have the best total cost of ownership (TCO) among major competitive models.

- Reliability:

- Patented lube-free differential valve ensures consistent operation.

- SimulShift (Pilot Valve) eliminates operational worries with reliable performance.

- Ease of Maintenance:

- Modular construction simplifies repairs and reduces downtime.

- Fewer parts and easy-to-use repair kits lower maintenance costs.

- Process-Ready Design:

- Offers electronic interface capability for precise flow control and consistent operation.

- Features such as End of Stroke (EOS) feedback and leak detection enhance operational monitoring.

Enhanced Productivity

- Maximizes flow rates while reducing pulsation and air consumption, ensuring efficient operation and improved throughput.

This 3” non-metallic ARO EXP diaphragm pump is ideal for industries needing reliable and high-performance liquid transfer solutions, such as chemical processing, food and beverage, water treatment, and more. Its advanced materials and features provide versatility to meet a wide range of operational demands.

|

Ratio |

1:1 |

|

Maximum GPM (LPM): |

285 GPM (1079 LPM) |

|

Air Inlet: |

3/4-14 NPT |

|

Fluid Inlet / Outlet |

3” DIN (8-Bolt) Flangeor |

|

Max. operating pressure psi (bar): |

120 psi (8.3 Bar) |

|

Suspended solids max. dia. in. (mm): |

3/8” (9.5mm) |

|

Weight lbs (kg): |

Polypropylene PVDF |

|

Maximum dry suction lift ft (m): |

20.5 ft. (6.3m) |

|

Sound Level: |

70 PSI |

|

Muffler Included: |

67389 |

Air Inlet Pressure Range. . . . . . . . . . . . 20 - 120 psig (1.4 - 8.3 bar)

Maximum Material Inlet Pressure. . . 10 psig (0.69 bar)

Fluid Outlet Pressure Range. . . . . . . . 20 - 120 psig (1.4 - 8.3 bar)

Maximum Flow Rate (flooded inlet). . . . . 285 gpm (1079 lpm)

Displacement / Cycle @ 100 psig. . . . 2.80 gal. (10.6 lit.)

Maximum Particle Size. . . . . . . . . . . . . 3/8” dia. (9.5 mm)

Maximum Temperature Limits (diaphragm / ball / seal material)

E.P.R./EPDM. . . . . . . . . . . . . . . . . -60° to 280° F (-51° to 138° C)

Hytrel®. . . . . . . . . . . . . . . . . . . . . . -20° to 180° F (-29° to 82° C)

Nitrile. . . . . . . . . . . . . . . . . . . . . . . 10° to 180° F (-12° to 82° C)

Polypropylene. . . . . . . . . . . . . . . 32° to 175° F (0° to 79° C)

PVDF (Kynar®).. . . . . . . . . . . . . . . 10° to 200° F (-12° to 93° C)

Santoprene®. . . . . . . . . . . . . . . . -40° to 225° F (-40° to 107° C)

PTFE. . . . . . . . . . . . . . . . . . . . . . . . 40° to 225° F (4° to 107° C)

Viton®. . . . . . . . . . . . . . . . . . . . . . . -40° to 350° F (-40° to 177° C)

Noise Level @ 70 psig - 60 cpm. . . . 85.3 dB(A)

- 66109 - Air Line Connection Kit: contains Piggyback Filter / Regulator, pipe nipple & 5’ section of hose

- 637369 - Air Motor Service Kit

- 6373447-AA, 637447-GG, 637447-TL, 637447-TT - Fluid Section Service Repair Kit

- End of Stroke Sensors: 97121 - Regular Duty

- Leak Detection: 67237 - Regular Duty