- Home

- Equipment

- Blackmer

- Sliding Vane Pumps

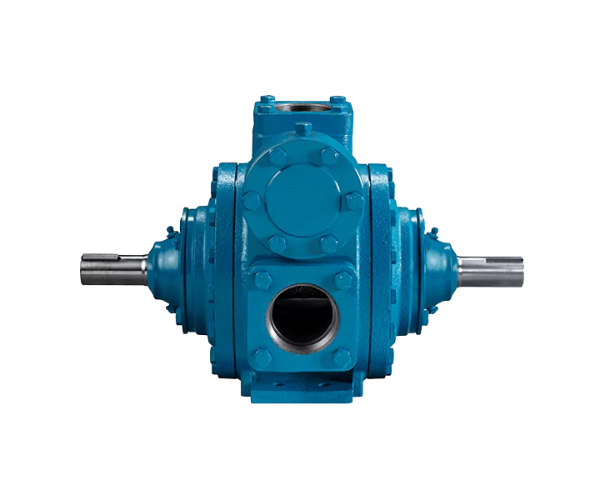

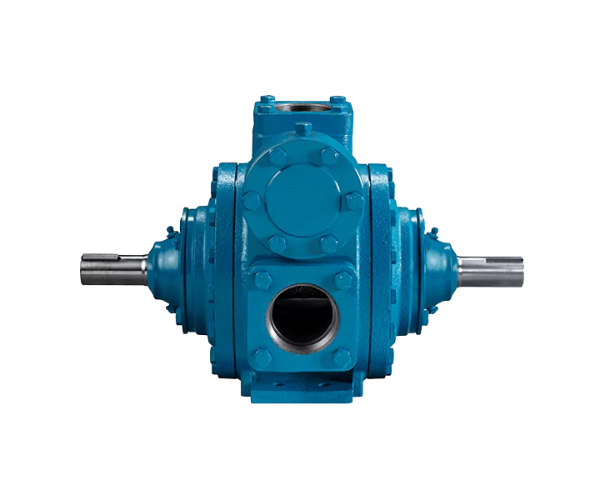

- Blackmer LGLD2 , LGLD3, LGLD4 – 2”, 3” and 4” LPG Transfer Sliding Vane Pump

Blackmer LGLD2 , LGLD3, LGLD4 – 2”, 3” and 4” LPG Transfer Sliding Vane Pump

The Blackmer LGLD2, LGLD3, and LGLD4 are specialized LPG transfer sliding vane pumps designed for handling propane, LPG, butane, and anhydrous ammonia across various applications, including bulk plant services, cylinder filling, vaporizers, bobtails, and transports.

Returns & Refunds Policy

Warranty Against Defects

Original Products

Ships Worldwide

Dedicate Support

- Description

- Brand

- Features

- Specifications

- Dimensions

- Materials

- Pump options

- Maintenance Kits

- Applications

The Blackmer LGLD2, LGLD3, and LGLD4 are specialized LPG transfer sliding vane pumps designed for handling propane, LPG, butane, and anhydrous ammonia across various applications, including bulk plant services, cylinder filling, vaporizers, bobtails, and transports.

Applications:

- Bobtail Service: The double-ended drive shaft of the LGLD2 and LGLD3 models makes them ideal for use on bobtail trucks.

- Transport Mounting: For the 3- and 4-inch models, mounting on transports is common, typically between tank landing gear brackets for optimal placement.

- Bulk Plant and Cylinder Filling: These pumps can handle both large-scale and smaller cylinder filling tasks with ease.

Advantages:

- Minimal Maintenance: The replaceable components and easy access to the pumping chamber make it simple to restore the pump to working condition.

- Reliability: The construction and engineering features, such as mechanical seals and external ball bearings, ensure minimal downtime and consistent performance.

- Safety: With an internal relief valve and certification for hazardous applications, these pumps are a reliable choice for safety-conscious users.

-

Versatility: These pumps can handle multiple fuels like propane, LPG, butane, and anhydrous ammonia, making them suitable for a variety of industrial applications.

-

Durable Construction: Built from ductile iron, the pumps are designed for long-lasting performance under demanding conditions. They are equipped with Blackmer’s mechanical seal and ball-bearing construction, ensuring reliability and minimal maintenance.

-

Cavitation Suppression: A unique feature of these pumps is their cavitation suppression liners, which effectively reduce noise, vibration, and wear caused by entrained vapors, enhancing operational efficiency.

-

Easy Maintenance: The internal pumping chamber can be easily restored to like-new condition through the replacement of the casing liner and end discs. This makes maintenance straightforward and cost-effective.

-

Internal Relief Valve: Each pump comes with an internal relief valve that protects the system from excessive pressures, ensuring safety and preventing damage.

-

Mounting Flexibility: The pumps can be mounted on bobtails, transports, or steel pads welded to tanks. The 3- and 4-inch models can be installed between tank landing gear brackets for added convenience.

-

Integrated Unit Assemblies: For ease of installation, Blackmer offers pre-configured assemblies that come with the motor, gearbox, baseplate, coupling safety covers, and the LGL Sliding Vane Pump. These assemblies are ready to install with no need for alignment, offering a streamlined solution for users.

-

Symmetrical Bearing Support: This design ensures even load distribution and minimal wear, extending the lifespan of the pump.

-

Certified for LPG and NH3: The pumps are certified by Underwriters Laboratory for use with LPG and anhydrous ammonia, adding a layer of safety and reliability.

-

Quiet Operation: The cavitation suppression liner and other features allow these pumps to operate quietly, providing an efficient and noise-reduced solution for transport and transfer systems.

AVAILABLE MODELS

- LGLD2

- LGLD3

- LGLD4

NOMINAL FLOW RATE RANGE

- LGLD2: 30 - 105 gpm (114 - 397 L/min)

- LGLD3: 60 - 201 gpm (227 - 761 L/min)

- LGLD4: 150 - 370 gpm (568 - 1,400 L/min)

MIN/MAX SPEED (RPM)

- LGLD2: 350 - 980

- LGLD3: 350 - 980

- LGLD4: 350 - 800

VISCOSITY

- 0.2 - 10 cP

VANE MATERIALS

- Duravane

MAXIMUM WORKING PRESSURE (MAWP)

- 350 psi (24.1 bar)

CONNECTION ORIENTATION

- Side Inlet | Top Outlet

DIFFERENTIAL PRESSURE

- 150 psi (10.3 bar)

PRIMARY MATERIALS OF CONSTRUCTION

- Ductile Iron

TEMPERATURE

- -25°F to 240°F (-32°C to 115°C)

AVAILABLE CERTIFICATES

- Hydrostatic Test

- Performance Test

- NPSH Test

- Material (actual or typical)

- Dimensional (pump only or unit)

|

PUMP MODEL |

L |

W |

H |

APPROX. WT. |

|

|

LGLD2 |

in |

13-4/9 |

9-11/16 |

10 |

85 lb |

|

mm |

341.3 |

246.1 |

254 |

38.6 kg |

|

|

LGLD3 |

in |

20-3/8 |

13-1/4 |

13-3/8 |

160 lb |

|

mm |

517.5 |

336.6 |

339.7 |

72.6 kg |

|

|

LGLD4 |

in |

16-3/8 |

16-15/16 |

15-4/9 |

205 lb |

|

mm |

415.9 |

430.2 |

392.2 |

93 kg |

|

PRESSURE PARTS |

|

|

Casing, Heads, Relief Valve Cover |

Ductile Iron: ASTM 536 |

|

Discs, Liner |

Cast Iron: ASTM A48 |

|

Bearing Covers |

Steel |

|

Bearing Locknut and Lockwasher |

Steel |

|

Rotor |

Ductile Iron: ASTM 536 |

|

Shaft |

High Strength Steel |

|

Relief Valve |

Cast Iron: ASTM A48 |

|

Relief Valve Spring |

Plated Steel |

|

OPTIONS |

DETAILS |

|

ORIENTATION OPTIONS |

Right Hand: INLET is to the right, when looking from driven side |

|

PORTING OPTION |

Top Outlet: Outlet 90º offset from inlet |

|

CONNECTION OPTIONS |

NPT (threaded) Welded |

|

MOUNTING OPTIONS |

Pump Only |

|

SEALING OPTIONS |

Blackmer single mechanical seal |

Vane Options

|

MATERIAL |

TEMPERATURE LIMITS |

VISCOSITY |

|

Duravane |

-25°F to 240°F (-32°C to 115°C) |

0.2 - 10 cP |

Elastomer Options

|

MATERIAL |

TEMPERATURE LIMITS |

|

Buna-N |

-25°F to 240°F (-31°C to 115°C) |

|

MODEL(S) |

DESCRIPTION |

PART NUMBER |

|

LGLD2E, LGL2E |

Kit - Maintenance – NH3 or Dual Service (QA) |

898979 |

|

LGLD2E |

Kit - Rebuild – NH3 or Dual Service (QA) |

899079 |

|

LGLD3F, LGL3F |

Kit - Maintenance – NH3 or Dual Service (QA) |

898981 |

|

LGLD3F |

Kit - Rebuild – NH3 or Dual Service (QA) |

899081 |

|

LGLD4B, LGL4B |

Kit - Maintenance |

898922 |

|

LGLD4B |

Kit - Rebuild (LGLD4B) |

899022 |

- Fuel oil

- Jet fuel & aviation fuel

- Gasoline

- Ethanol & other alcohols

- Lube oil

- Solvents

- Ester

- Ketone

- Naphtha

- Ether

- Amine

- Aromatic

- Terpene

- Glycol

- Additives