- Home

- Equipment

- Blackmer

- Sliding Vane Pumps

- Blackmer Pump TX1.5A, TXD2A, TXD2.5A and TXD3A Sliding Vane Pumps

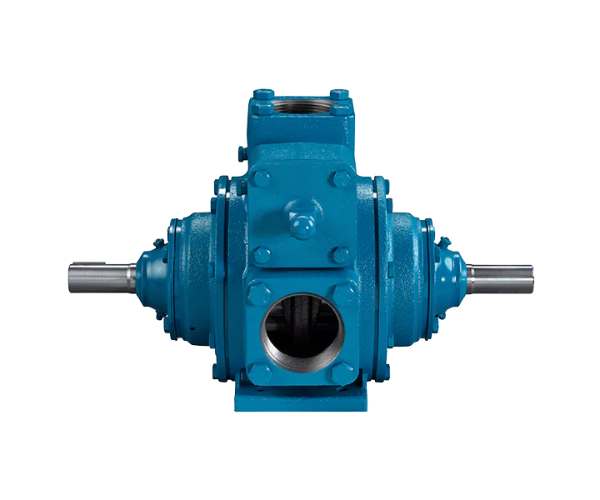

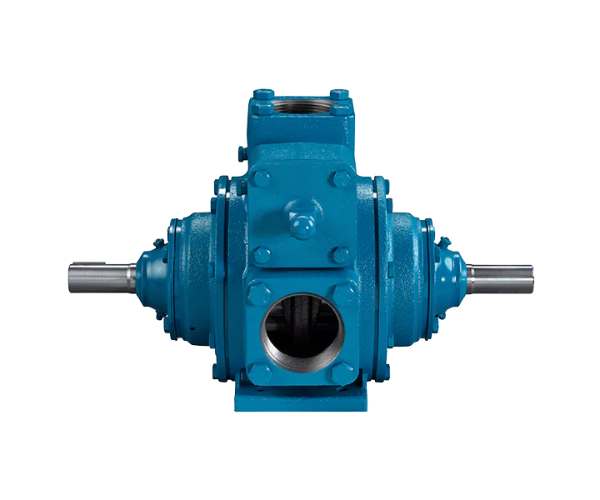

Blackmer Pump TX1.5A, TXD2A, TXD2.5A and TXD3A Sliding Vane Pumps

The Blackmer TX/TXD/TXDI Series Sliding Vane Pumps are high-performance, durable pumps designed for reliable, trouble-free operation, even with challenging fluids.

Returns & Refunds Policy

Warranty Against Defects

Original Products

Ships Worldwide

Dedicate Support

The Blackmer TX/TXD/TXDI Series Sliding Vane Pumps are high-performance, durable pumps designed for reliable, trouble-free operation, even with challenging fluids. These pumps, part of the Iron Line, are engineered for quick, silent operation and offer extended service life with minimal maintenance.

-

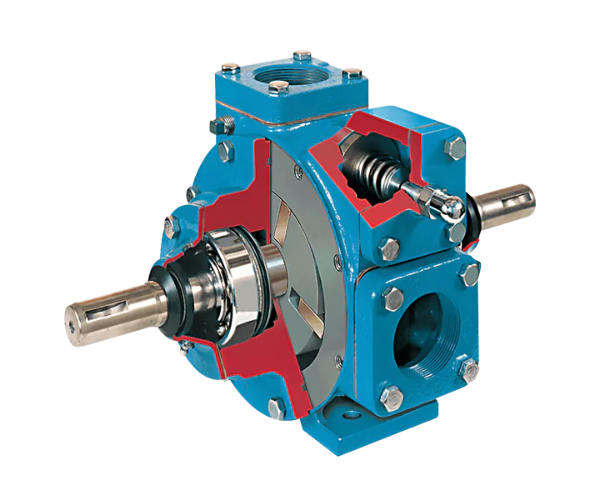

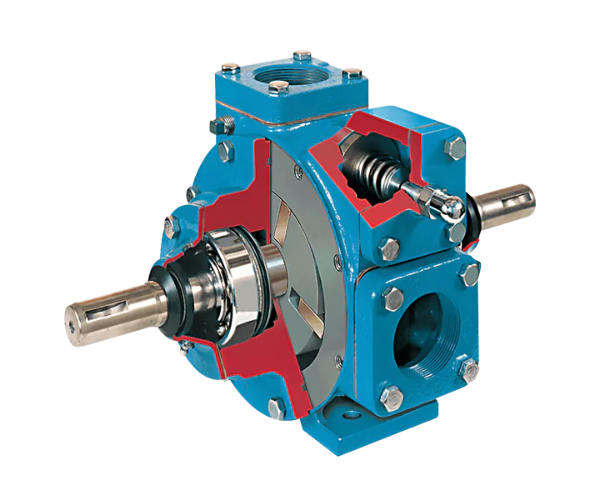

Sliding Vane Design:

- Offers reliable and consistent performance.

- Automatically adapts to wear, maintaining flow rates over time.

- Ideal for non-lubricating liquids, ethanol, and biodiesel.

-

Dual-Ended Drive Shaft:

- Supports clockwise (RH) or counterclockwise (LH) rotation.

- Simplifies installation with the 2-, 2.5-, and 3-inch models.

- Roller ball bearings provide external support for rotor stability.

-

High Efficiency and Low Power Requirements:

- High volumetric efficiency results in reduced power requirements.

- This leads to cost savings in motor operation and electricity.

-

Extended Dry-Run Capability:

- The internal mechanical seals enable continued operation without lubrication.

- Excellent suction lift and line-stripping capabilities.

-

Corrosion-Resistant Features:

- Blackmer mechanical seals and FKM O-rings are resistant to a wide range of chemicals.

- Optional Buna or PTFE elastomers and seals for additional chemical resistance.

-

Symmetrical Bearing Support:

- Ensures even wear and prolonged operational life.

- Isolates external bearings from the pumpage to maximize bearing life and minimize contamination risks.

-

Maintenance-Friendly:

- Vanes can be replaced without removing the pump from service.

- Pneumatic relief valves and adjustable relief valves protect the pump from excessive pressure, ensuring safety and longevity.

-

Self-Priming & Dry-Run Capabilities:

- This pump has remarkable self-priming capabilities and effective dry-run operation.

-

Strainers:

- T-type strainers are available to prevent damage from foreign matter, like welding slag, in the system.

-

Cost-Effective:

- Lower operational costs due to high efficiency and reduced maintenance needs.

- Suitable for continuous operation, making it an ideal choice for high-demand industries.

AVAILABLE MODELS

- TX1.5

- TXD(I)2

- TXD(I)2.5

- TXD(I)3

- TX(I)4

NOMINAL FLOW RATE

- TX1.5: 56 gpm (212 L/min)

- TXD(I)2: 87 gpm (329 L/min)

- TXD(I)2.5: 157 gpm (594 L/min)

- TXD(I)3: 270 gpm (1,022 L/min)

- TX(I)4: 505 gpm (1,911 L/min)

CATALOG OPTIONS

- Connections: NPT, Weld, Victaulic

- Elastomers: BUNA, FKM, PTFE

- Valve: Corrosion resistant

- Bypass: 1-stage or pneumatic 2-stage

- Inlet Strainer, Hydraulic Motor Adapter

DIFFERENTIAL PRESSURE

- 125 psi (8.6 bar)

MAXIMUM WORKING PRESSURE (MAWP)

- 175 psi (15.5 bar)

VISCOSITY

- 1.0 - 4250 cP

VANE MATERIALS

- Duravane

- Bronze

PRIMARY MATERIALS OF CONSTRUCTION

- TX & TXD: Cast Iron

- TXI & TXDI: Ductile Iron

CONNECTION ORIENTATION

- TX & TXD: Side Inlet | Top Outlet

- TXI & TXDI: Side Inlet | Side Outlet

TEMPERATURE

- -25°F to 240°F (-32°C to 115°C)

MIN/MAX SPEED (RPM)

- TX1.5: 200 - 800

- TXD(I)2 & TXD(I)2.5: 70 - 780

- TXD(I)3: 70 - 640

- TX(I)4: 70 - 520

AVAILABLE CERTIFICATES

- Hydrostatic Test

- Performance Test

- NPSH Test

- Material (actual or typical)

- Dimensional (pump only or unit)

|

PUMP MODEL |

|

L |

W |

H |

APPROX. WT. |

|

TX1.5 |

in |

12-7/8 |

10-4/7 |

8-1/2 |

61 lb |

|

mm |

327 |

287.3 |

215.9 |

27 kg |

|

|

TX(D)2A, TXDI2 |

in |

16-3/4 |

10 |

8-11/16 |

70 lb |

|

mm |

425.5 |

254 |

220.6 |

32 kg |

|

|

TX(D)2.5A, TXDI2.5 |

in |

18-1/4 |

10-3/4 |

9-5/8 |

94 lb |

|

mm |

463.6 |

273.1 |

244.5 |

43 kg |

|

|

TX(D)3E, TXDI3 |

in |

20 1/3 |

13 1/2 |

12 4/5 |

152 lb |

|

mm |

515.9 |

342.9 |

325.4 |

69 kg |

|

|

TX4A, TXI4 |

in |

19-1/4 |

16-1/2 |

15-1/2 |

295 lb |

|

mm |

489 |

419.1 |

393.7 |

134 kg |

|

PRESSURE PARTS |

PUMP MODEL |

MATERIAL |

|

Cylinder |

TX1.5–3 |

Cast Iron: ASTM A48 |

|

TX4 & TXDI2-4 |

Ductile Iron: ASTM 536 |

|

|

Heads |

TX1.5–3 |

Cast Iron: ASTM A48 |

|

TX4 & TXDI2-4 |

Ductile Iron: ASTM 536 |

|

|

Relief Valve Cover |

TX1.5–3 |

Cast Iron: ASTM A48 |

|

TX4 & TXDI2-4 |

Ductile Iron: ASTM 536 |

Pump Options

|

ORIENTATION OPTIONS |

Double End: drive pump from either side |

|

|

PORTING OPTIONS |

TX/TXD: Top Outlet: Outlet 90° offset from inlet |

|

|

CONNECTION OPTIONS |

NPT (threaded) |

|

|

MOUNTING OPTIONS |

Pump Only |

|

|

SEALING OPTIONS |

Blackmer single mechanical seal |

Vane Options

|

MATERIALS |

TEMPERATURE LIMITS |

VISCOSITY |

|

Duravane |

-25°F to 240°F (-32°C to 115°C) |

0.2 - 4250 cP |

Elastomer Options

|

MATERIALS |

TEMPERATURE LIMITS |

|

FKM |

-15°F to 240°F (-26°C to 115°C) |

|

Buna-N |

-25°F to 240°F (-32°C to 115°C) |

|

PTFE - SS Spring |

0°F to 240°F (-18°C to 115°C) |

|

MODEL(S) |

DESCRIPTION |

PART NUMBER |

|

TX1.5 |

Kit - Maintenance, Buna-N |

898949 |

|

TX1.5 |

Kit - Maintenance, FKM |

899179 |

|

TXD2A, TX2A, TXD2A-AVA |

Kit - Maintenance, Buna-N |

898950 |

|

TXD2A |

Kit - Maintenance |

898956 |

|

TXD2.5A, TX2.5A, TXD2.5A-AVA |

Kit - Maintenance, Buna-N |

898951 |

|

TXD2.5A |

Kit - Maintenance |

898957 |

|

TXD3E, TX3E |

Kit - Maintenance, Buna-N |

898952 |

|

TXD3E |

Kit - Maintenance |

898958 |

|

TX4A |

Kit - Maintenance, Buna-N |

898953 |

|

TX4A |

Kit - Maintenance |

898959 |