- Home

- Equipment

- Leading Corken Pumps Supplier in UAE

- LPG Pumps

- Corken Hydraulic Option For Sliding Vane Pumps

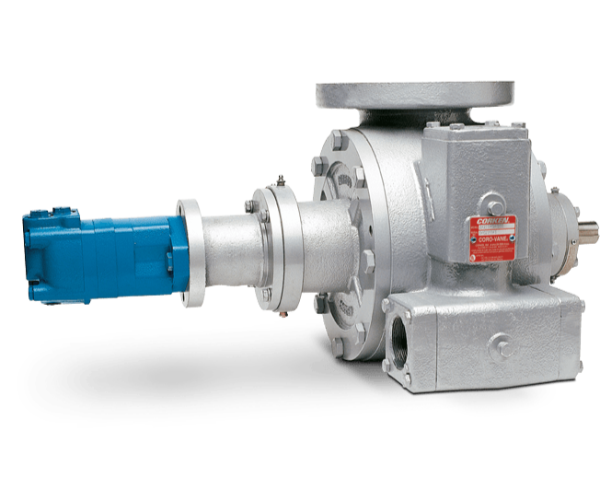

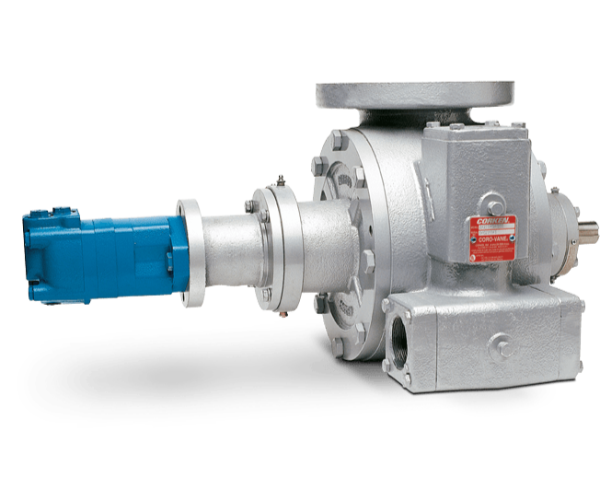

Corken Hydraulic Option For Sliding Vane Pumps

When an electric motor drive is not suitable due to space constraints, alignment issues, or other factors, a hydraulic drive offers a viable solution. This setup allows the hydraulic motor to be directly mounted to the pump, providing several key advantages:

Returns & Refunds Policy

Warranty Against Defects

Original Products

Ships Worldwide

Dedicate Support

- Description

- Brand

- Operating Specifications

- Construction

- Materials

- Features

- Liquids

- Applications

- Markets

-

Compact and Precise Alignment: The hydraulic motor is mounted directly to the pump, ensuring a precise and compact alignment without the need for complex coupling systems. This simplifies installation and reduces the risk of misalignment.

-

Space-Saving: Ideal for applications where space is limited or where an electric motor cannot be easily accommodated. The hydraulic drive eliminates the need for additional electrical components, making the setup more space-efficient.

-

Flexibility: Hydraulic drives offer versatility, as they can be used in environments where electric power is not available or where it is undesirable to use an electric motor (such as in hazardous or explosive environments).

-

Suitable for Various Models: The hydraulic drive option is available with CD, PT, and PZ model pumps, making it a flexible choice for different pump types.

-

Reduced Maintenance Issues: Directly coupling the hydraulic motor to the pump can help reduce wear and tear caused by misalignment and can eliminate potential mechanical failures associated with more complex drive systems.

- Flow rates up to 400 gpm (1,514 lpm)

- Working pressures up to 400 psi (27.6)

- Differential pressures up to 125 psi (8.6 bar)

- Temperature range: -25 to 225 °F (-32 to 107 °C)

- Viscosity up to 20,000 SSU (4,250 cSt)

-

Foot Mount Design Compatibility:

- Available for a variety of pump models, including CP, CD, PT, PZ, and Z models.

- Hydraulic versions of these pumps are designated as CPH, CDH, PTH, and PZH, indicating their hydraulic drive capability.

-

Truck Mount Compatibility:

- The hydraulic pump can be used with Z-model truck mount designs, such as the ZH200, ZH3200, and ZH4200.

- This ensures that these pumps can be integrated into truck-mounted systems, making them ideal for mobile or remote applications.

-

Six Vane/Blade Design:

- These pumps use a six vanes/blades design, which enhances performance by providing smooth flow, reducing pulsation, and increasing operational efficiency.

- The vane drivers ensure that the blades are properly engaged, contributing to consistent performance and durability.

-

Mechanically Sealed Pump:

- The pump features a mechanical seal, ensuring excellent sealing performance and minimizing the risk of leakage during operation.

- A wide variety of sealing options are available to suit different application requirements, providing flexibility for various operational environments.

-

Flange Options:

- Depending on the model, the pump can be configured with either NPT (National Pipe Thread) or ANSI (American National Standards Institute) flanges. This makes the pump compatible with a wide range of piping and installation standards, allowing for easier integration into different systems.

-

Pump Casing and Heads:

- Gray Iron or Ductile Iron: Both materials offer excellent strength and durability. Gray iron is typically used for its good castability and damping properties, while ductile iron provides greater toughness and resistance to fatigue and impact, making it suitable for high-stress applications.

-

Cam and Side Plates:

- Gray Iron: This material is chosen for its wear resistance, strength, and ease of casting. It also helps in reducing vibration and noise, contributing to smoother pump operation.

-

Rotor and Flanges:

- Ductile Iron: Offers enhanced strength, impact resistance, and durability. Ductile iron is ideal for components that undergo high stress and pressure, like rotors and flanges.

-

Seal Seat:

- Gray Iron, Stainless Steel, or Ni-Resist: The seal seat is a critical component for preventing leakage, and the material choice varies based on application needs:

- Gray Iron is durable and cost-effective for many standard applications.

- Stainless Steel provides superior corrosion resistance, ideal for harsh or chemically aggressive environments.

- Ni-Resist is a high-nickel cast iron with excellent corrosion and heat resistance, often used in high-performance or harsh operating conditions.

- Gray Iron, Stainless Steel, or Ni-Resist: The seal seat is a critical component for preventing leakage, and the material choice varies based on application needs:

-

O-Rings:

- Available in a variety of materials:

- Buna-N: A general-purpose rubber that provides good oil and fuel resistance.

- PTFE (Polytetrafluoroethylene): Known for excellent chemical resistance and high-temperature stability.

- Viton®: A high-performance material with outstanding resistance to heat, chemicals, and oils. (Registered trademark of DuPont)

- Neoprene®: Offers good oil and weathering resistance. (Registered trademark of DuPont)

- Available in a variety of materials:

-

Blades:

- Advanced Polymers: These blades are made from advanced polymer materials, which are designed for superior wear resistance, flexibility, and low friction. This allows for efficient and long-lasting performance in the pump, reducing maintenance requirements.

-

Eliminates the Need for an Electric Motor:

- The hydraulic drive system eliminates the need for an electric motor, making the pump ideal for applications where electric power is unavailable, not preferred, or space is limited. This provides a more compact and flexible solution.

-

Self-Adjusting Sliding Vanes:

- The self-adjusting sliding vanes optimize the pump’s performance by ensuring that the vanes maintain proper contact with the pump casing, compensating for wear over time. This results in improved efficiency and consistent operation, even as the pump ages.

-

Replaceable and Reversible Cam and Side Plates:

- Cam and side plates can be replaced if they wear out, allowing for easy repairs and longer pump life.

- Reversible side plates enhance the flexibility of the pump by allowing you to switch the sides of the plates to extend their life before needing a full replacement.

-

Simple and Cost-Effective Maintenance:

- Maintenance is easy and cost-effective. By removing the pump head, you can access and replace the internal components (such as vanes and seals) without needing to disturb the piping or other surrounding infrastructure. This reduces downtime and simplifies service.

-

Ability to Handle Small Amounts of Vapor:

- The pump can handle small amounts of vapor, which is valuable for applications where liquid may have some level of gas or vapor entrainment. This feature helps the pump maintain its performance even when there is some variation in the material being pumped.

-

Excellent Suction Lift:

- The pump provides excellent suction lift, which allows it to clear both suction and discharge lines efficiently. This capability is particularly useful for priming or clearing lines in applications where air or vapor may be present.

- Aviation fuels

- Fuel oils

- Lube oils

- Solvents

- Liquefied gases

- Many more light liquids

- Terminal

- Bulk plant

- Truck and Transport

- Mobile (trailers & portable skid units)

- Alternative fuels

- Liquefied gases

- Truck & transport

- Liquid terminals