- Home

- Equipment

- Leading Corken Pumps Supplier in UAE

- Compressors

- Corken Plant Oil Extraction Compressor System

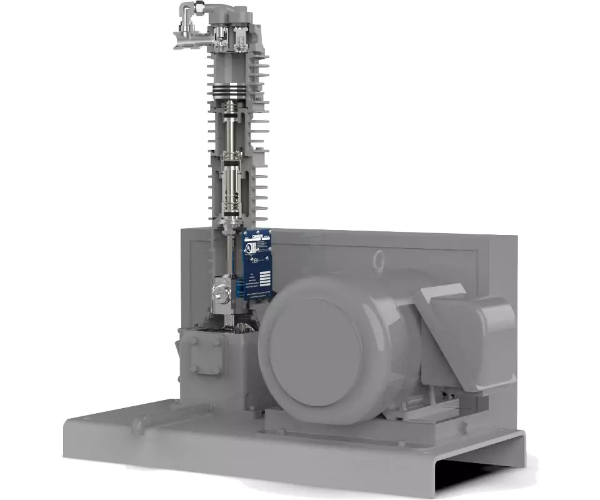

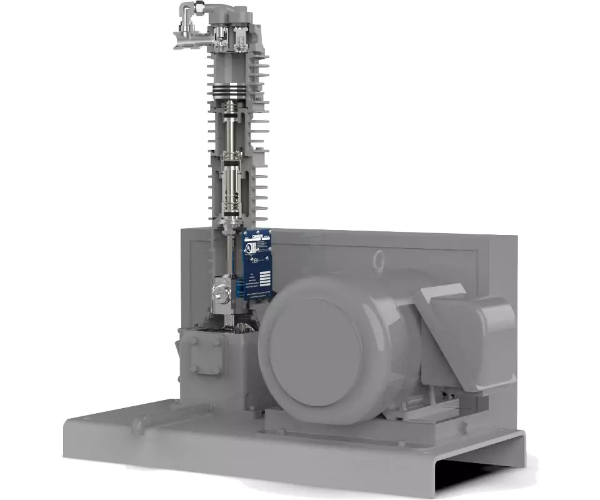

Corken Plant Oil Extraction Compressor System

Corken has established itself as the market leader in providing gas compression and industrial pumps to critical sectors including LPG, petrochemical, chemical, and gas processing industries. Over nearly a century, Corken has built a reputation for delivering reliable, high-performance solutions tailored to meet the evolving needs of industrial operations.

Returns & Refunds Policy

Warranty Against Defects

Original Products

Ships Worldwide

Dedicate Support

Plant Oil Extraction and Hydrocarbon Processing

Since ancient times, plant chemicals have been recognized for their nutritional and therapeutic benefits. As scientific knowledge expanded, plant oil extraction became a key method for isolating desired components, with hydrocarbon extraction emerging as one of the most efficient and cost-effective techniques.

Other extraction methods, such as using ethanol or carbon dioxide (CO₂), are also available, but hydrocarbon extraction remains widely favored for its superior performance in separating target substances from plant materials.

Key Requirements in Plant Oil Extraction

- Safety and Compliance:

- Ensuring equipment meets stringent safety standards, particularly for indoor production environments.

- Efficiency:

- Utilizing equipment that optimizes the extraction process for maximum yield.

Corken E91 Compressor: The Only Fully UL Certified Solution

The Corken E91 Compressor stands out as the only fully UL Certified compressor system specifically designed for the plant oil extraction industry.

Certifications and Compliance

- UL Certification for Indoor Use:

- Guarantees safety and performance in varied indoor production environments.

- Good Manufacturing Practice (GMP):

- Ensures adherence to high standards for safe and effective product manufacturing.

- ISO 9001 & ISO 14001 Standards:

- Certifies quality and environmental management systems.

- ATEX and EU Machinery Directives:

- Demonstrates compliance with European safety and operational regulations.

Corken’s Commitment to Excellence

With a strong foundation in innovation and quality, Corken provides robust solutions for challenging industrial applications. The company’s leadership in gas compression, pumps, and certified equipment makes it the preferred choice for industries worldwide, ensuring safety, efficiency, and reliability in every operation.

Cylinder Dimensions

- Bore of Cylinder:

- 3.0 inches (76.2 mm).

- Stroke:

- 2.5 inches (63.5 mm).

Performance Metrics

- Piston Displacement:

- Minimum @ 400 RPM: 4.1 CFM (7.0 m³/h).

- Maximum @ 825 RPM: 8.4 CFM (14.3 m³/h).

- Maximum Working Pressure:

- 335 psig (23.1 bar G).

- Maximum Brake Horsepower:

- 7.5 HP (5.6 kW).

- Maximum Rod Load:

- 3,600 lb (1,632.9 kg).

- Maximum Outlet Temperature:

- 350°F (177°C).

- Head and Cylinder: Ductile iron for strength and wear resistance.

- Crosshead Guide, Crankcase, Flywheel, Bearing Carrier: Gray iron for durability and vibration damping.

- Valve Seat and Bumper: Stainless steel or ductile iron for operational flexibility.

- Valve Plate: PEEK or stainless steel for durability and performance.

- Valve Spring: Stainless steel for resilience and repeated compression cycles.

- Pistons: Ductile iron, gray iron, or stainless steel for robust operation.

- Piston Rings: PTFE (glass and moly filled) for low friction and sealing.

- V-Ring Packing: PTFE (glass and moly filled) for superior durability.

- Packing Cartridge: Ductile iron for structural integrity.

- Crankshaft: Ductile iron for heavy load handling.

- Connecting Rod: Ductile iron for reliable performance under stress.

- Connecting Rod Bearing: Bimetal Babbitt for wear resistance.

- Wrist Pin: Steel for strength and reliability.

- Wrist Pin Bushing: Bronze for wear resistance.

- Main Bearing: Tapered roller bearings for precise alignment and heavy loads.

- O-Rings: Buna-N or Neoprene® for sealing and chemical resistance.

- Faster Vapor Recovery: Reduces cycle times, increasing product yield.

- Food Grade Material Used: Viton®, PTFE, and nickel-coated components for compliance and durability.

- Self-Lubricating: Triple PTFE seals for leak protection and extended life.

- Quiet Operation: Ideal for indoor use (~85 dBA at 3 ft. range).

- Oil-Free Gas Compression: Eliminates risk of process gas contamination.

- Adjustable Packing Screw: Extends packing life and minimizes downtime.

- Self-Contained: No need for an external air compressor or pneumatic driver.

- Regulatory Approved: Meets industry safety standards for plant oil extraction.

- Safety Switches: UL/CSA approved power, pressure, and temperature safety switches available.

- Optional Purge Kit: Complies with U.S. EPA Regulations (40 CFR CH Section 264.1053).

- Compressor Speed: 700 RPM.

- Vapor Temperature: 70°F (21.1°C).

- Final Evacuation Pressure: 0 psig (0 bar G).

- Average Recovery Rate (lb/hr):

- Butane: 93.

- Propane: 240.

- Note: Suction pressure changes throughout the process; averages are calculated between starting and final suction pressures.

- Disclaimer: This table is for illustrative purposes only; contact Corken for precise sizing for your application.