- Home

- Equipment

- Ingersoll Rand Pumps

- Vacuum Boosters

- Tuthill MD Vacuum Booster 3200-7300

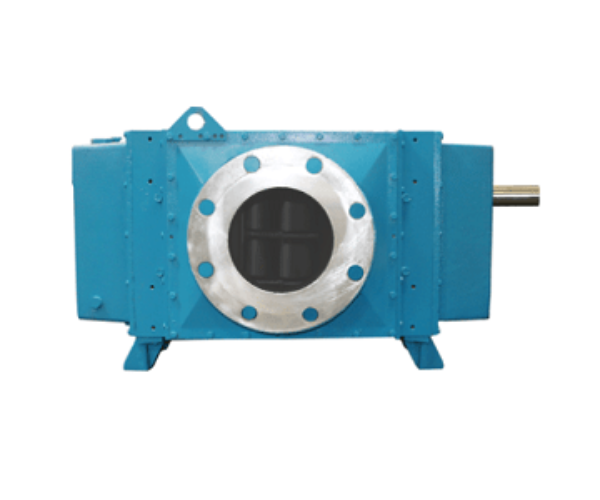

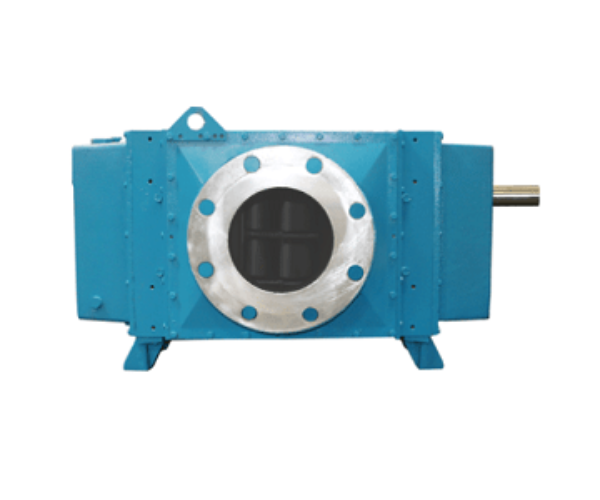

Tuthill MD Vacuum Booster 3200-7300

The Tuthill MD Vacuum Booster Series 3200-7300 is designed to enhance the performance of vacuum systems by increasing the pumping speed and achieving deeper vacuum levels.

Returns & Refunds Policy

Warranty Against Defects

Original Products

Ships Worldwide

Dedicate Support

The Tuthill MD Vacuum Booster Series 3200-7300 is designed to enhance the performance of vacuum systems by increasing the pumping speed and achieving deeper vacuum levels. These vacuum boosters are widely used across various industries such as chemicals, petrochemicals, plastics, semiconductors, food processing, and vacuum furnace applications.

-

Mechanical Seals, Integral Pressure Lubrication:

- These models use mechanical seals on the rotor shafts and drive shaft.

- Flanged port fittings and water-cooled drive shaft seals are standard.

- An integral pressure lubrication system with a water-cooled heat exchanger is included.

- Cooling coils in the end covers are part of this configuration (excluding optional motor mounting flange versions).

-

Slinger Seals, Integral Pressure Lubrication:

- The models utilize a mechanical drive shaft seal combined with a non-contacting, non-wearing slinger seal on the rotor shafts.

- This configuration includes water-cooled drive shaft seals and flanged port fittings.

- It has an integral pressure lubrication system with a water-cooled heat exchanger, though cooling coils are not included.

-

Low Mechanical Noise:

- Designed to operate at low noise levels, with an output of 82 dB(A) or less at blank-off. This measurement excludes motor and background noise, ensuring quieter operation in industrial environments.

-

Special Materials:

- Standard construction materials include cast iron housing, ductile iron rotors and shafts, and end plates with port fittings.

- Special materials (available for select models) include stainless steel, carbon steel, or additional coatings like Bi-Protec® (Nickel/Armoloy® special coating) for added durability.

-

Optional Motor Mounting Flanges:

- These models come with optional flange adapters for mounting NEMA C-face motors (up to 75 HP) or IEC D-flange motors (up to 55 kW).

- This option eliminates the need for a separate base-mounted assembly and coupling guard, simplifying installation and reducing space requirements.

-

Metric Availability:

- These boosters are available with metric drive shafts and process connections for compatibility with international standards.

-

Special Testing:

- The boosters undergo a variety of specialized tests, including ASME PTC-9 testing, hydrostatic testing up to 150 PSIG (10.35 bar g), and pressure gas testing up to 100 PSIG (6.9 bar g).

- Seal leakage testing ensures the reliability and tightness of the system.

- Chemical & Petrochemical Production

- Plastics Manufacturing

- Semiconductor Production

- Wood Composites Manufacturing

- Food Processing

- Vacuum Furnace Applications

- General Industrial Applications

| Model | CFM / m3/h |

| 150 | 50-150 / 85- 255 |

| 240 | 70-230 / 119-391 |

| 400 | 120-400 / 204-680 |

| 540 | 170-540 / 289-918 |

| 720 | 230-720 / 391-1223 |

| 850 | 270-850 / 459-1444 |

| 1200 | 400-1240 / 680-2107 |

| 1600 | 500-1600 / 850-2718 |

| 2000 | 650-2000 / 1104-3398 |

| 2700 | 850-2700 / 1444-4587 |

| 1800 | 680-1800 / 1155-3058 |

| 2200 | 860-2300 / 1461-3908 |

| 2900 | 1130-3000 / 1920-5097 |

| 3600 | 1400-3600 / 2379-6116 |

| 4500 | 1730-4500 / 2939-7646 |

| 3200 | 800-3200 / 1359-5437 |

| 4200 | 1000-4200 / 1699-7136 |

| 5400 | 1400-5700 / 2379-9684 |

| 7300 | 1800-7400 / 3058-12573 |

| 4000 | 890-4000 / 1512-6796 |

| 6500 | 1400-6400 / 2379-10874 |

| 7900 | 1800-8000 / 3058-13592 |

| 8000 | 2100-9500 / 3568-16141 |

| 10000 | 2800-10000 / 4757-16990 |