- Home

- Equipment

- Wilden

- Air Operated Double Diaphragm Pumps in UAE

- Wilden 51 mm (2") Pro-Flo® Series Bolted Metal AODD Pump

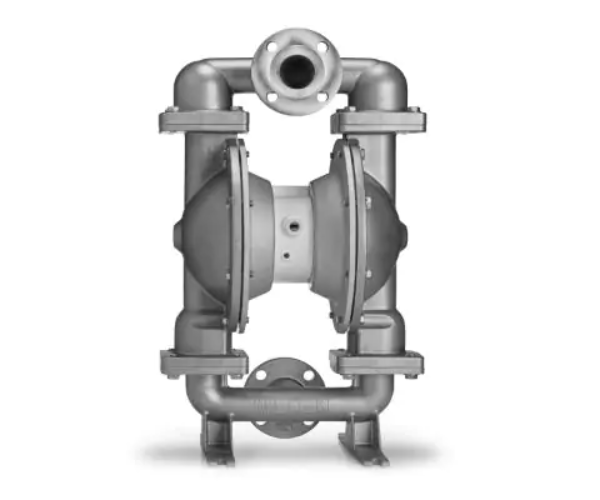

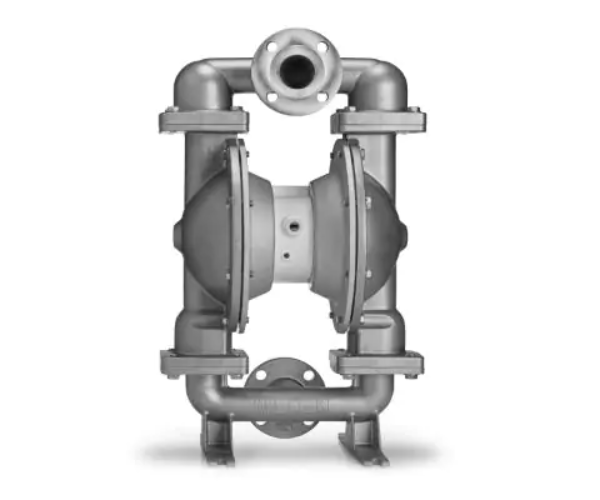

Wilden 51 mm (2") Pro-Flo® Series Bolted Metal AODD Pump

The Wilden 51 mm (2") Pro-Flo® Series Bolted Metal AODD Pump is designed for high-performance applications, setting a new standard in pump technology with a range of features

Returns & Refunds Policy

Warranty Against Defects

Original Products

Ships Worldwide

Dedicate Support

- Description

- Brand

- Features

- Specifications

- Dimensions

- Performance Curve

- Wetted/Non-Wetted Housings

- Elastomer Options

- Accessories

The Wilden 51 mm (2") Pro-Flo® Series Bolted Metal AODD Pump is designed for high-performance applications, setting a new standard in pump technology with a range of features

- Bolted Construction: Offers superior flow rates, up to 35% higher than competing models, and longer diaphragm life due to an improved flow path design.

- Simple Replacement: The bolted-down footprint and inlet/discharge connections are identical to Wilden's clamped counterparts, making it easy to replace.

- Greater Containment: Built to offer enhanced containment capabilities for various industrial uses.

- Threaded Inlet/Discharge Connections: Available in NPT or BSPT (P820 model).

- No-Weld or Nipple Attachment: Options for DIN or ANSI flanged inlet/discharge connections (P830 model).

- Extensive Chemical Compatibility: The pump is designed to handle a wide range of chemicals, making it versatile for various industries.

- Submersible and Portable: It is suitable for both submersible and portable use, offering flexibility in different environments.

- Large Passage and High-Lift Suction: Ensures efficient flow and the ability to handle high-lift suction applications.

- Ease of Use and Maintenance: The design ensures simple operation and ease of upkeep, reducing downtime.

- Adjustable Internal Manifolds: Features manifolds with adjustable internal settings for increased customization and efficiency.

- Increased Dependability: The pump has been designed for long-term reliability, ensuring longer mean time between repairs (MTBR) and less frequent maintenance.

AIR INLET

- 1/2" FNPT

LIQUID INLET

- 51 mm (2")

LIQUID DISCHARGE

- 51 mm (2")

CONNECTION TYPE

- NPT/BSPT (Threaded)

- DIN/ANSI (Flanged)

MAX FLOW RATE

- Rubber – 609 lpm (161 gpm)

- EZ-Install TPE – 605 lpm (160 gpm)

- Full-Stroke PTFE – 590 lpm (156 gpm)

- Reduced-Stroke PTFE – 492 lpm (130 gpm)

MAX PRESSURE

- 8.6 bar (125 psi)

MAX DIAMETER SOLIDS

- 6.4 mm (1/4")

MAX SUCTION LIFT CAPABILITY

- Rubber – 7.4 m (24.3') Dry, 9.0 m (29.5') Wet

- EZ-Install TPE – 6.7 m (21.9') Dry, 9.0 m (29.5') Wet

- Full-Stroke PTFE – 6.9 m (22.6') Dry, 9.0 m (29.5') Wet

- Reduced-Stroke PTFE – 4.6 m (15.1') Dry, 9.0 m (29.5') Wet

DISPLACEMENT PER STROKE*

- Rubber –2.8 L (0.74 gal)

- EZ-Install TPE – 2.5 L (0.67 gal)

- Full-Stroke PTFE – 2.5 L (0.65 gal)

- Reduced-Stroke PTFE – 1.7 L (0.46 gal)

*1 cycle = 2 stroke

|

ITEM |

METRIC (mm) |

STANDARD (inch) |

|

A |

453 |

17.9 |

|

B |

48 |

1.9 |

|

C |

346 |

13.6 |

|

D |

630 |

24.8 |

|

E |

670 |

26.4 |

|

F |

62 |

2.4 |

|

G |

347 |

13.7 |

|

H |

93 |

3.7 |

|

J |

177 |

7.0 |

|

K |

338 |

13.3 |

|

L |

510 |

20.1 |

|

M |

324 |

12.8 |

|

N |

257 |

10.1 |

|

P |

229 |

9.0 |

|

R |

254 |

10.0 |

|

S |

14 |

0.6 |

|

ITEM |

METRIC (mm) |

STANDARD (inch) |

|

A |

452 |

17.8 |

|

B |

64 |

2.5 |

|

C |

354 |

14.0 |

|

D |

620 |

24.4 |

|

E |

658 |

25.9 |

|

F |

58 |

2.3 |

|

G |

356 |

14.0 |

|

H |

93 |

3.7 |

|

J |

178 |

7.0 |

|

K |

338 |

13.3 |

|

L |

510 |

20.1 |

|

M |

305 |

12.0 |

|

N |

254 |

10.0 |

|

P |

229 |

9.0 |

|

R |

254 |

10.0 |

|

S |

15 |

0.6 |

P820/P830 METAL RUBBER-FITTED

P820/P830 METAL REDUCED-STROKE PTFE-FITTED

Max. Flow Rate: 492Ipm (130 g pm)

Max. Inlet Pressure: 8.6 bar (125 psig)

Max. Solids Passage: 6.4 mm (1/4")

Suction Lift: 4 6 m Dry (15.1') 9 0 m Wet (29.5')

Wetted Housings

| MATERIAL | SHIP WEIGHT |

|---|---|

| Aluminum | 47 kg (104 lb) (P820) 54 kg (118 lb) (P830) |

| Stainless Steel | 73 kg (161 lb) (P820) 81 kg (178 lb) (P830) |

| Ductile Iron | 71 kg (156 lb) (P820) 82 kg (181 lb) (P830) |

Non-Wetted Housings

| DESCRIPTION | MATERIAL |

|---|---|

| Center Section | Polypropylene |

| Air Valve | Polypropylene |

| Air Chamber | Aluminum |

| MATERIAL | TEMPERATURE LIMITS |

|---|---|

| Buna-N | -12°C to 82°C (10°F to 180°F) |

| EPDM | -51°C to 138°C (-60°F to 280°F) |

| FKM | -40°C to 177°C (-40°F to 350°F) |

| Geolast® | -40°C to 82°C (-40°F to 180°F) |

| Neoprene | -18°C to 93°C (0°F to 200°F) |

| PTFE* | 4°C to 104°C (40°F to 220°F) |

| Polyurethane | -12°C to 66°C (10°F to 150°F) |

| Saniflex™ | -29°C to 104°C (-20°F to 220°F) |

| Wil-Flex™ | -40°C to 107°C (-40°F to 225°F) |

* 4°C to 149°C (40°F to 300°F) - 13 mm (1/2") and 25 mm (1") models only

- Spare Parts

- Equalizer® Surge Dampeners - SD Series

- Wil-Gard™ Diaphragm Monitoring System

- Pump Cycle Monitor